Share the page

RE&UP, circular technology serving climate mitigation

Published on

Private Sector & Development - Business & Climate: Acting to transform

Proparco has published a new edition of its Private Sector & Development magazine, focusing on the strategic role of the private sector and financial institutions in tackling the climate emergency.

In Gaziantep, in south-eastern Turkey, SANKO Group is revolutionising the field of textile recycling. Its subsidiary RE&UP – which has partnered with a French company for its production machinery – combines cutting-edge technology, industrial performance and significant environmental benefits to mitigate the impact of an industry that has traditionally been a big environmental polluter. This project has received €70 million in strategic funding from Proparco.

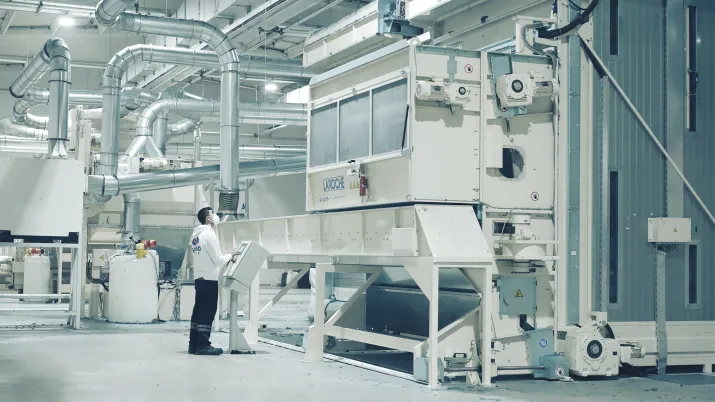

Amidst the huge bales of textile waste being fed into stateof-the-art robotic production lines, a quiet revolution is taking place, far from the fashion catwalks. At RE&UP’s industrial-scale facility in Gaziantep, a new generation of textile recycling is being shaped by SANKO Group, a global leader in industrial innovation. Here, bold ecological ambition meets cutting-edge technology to transform waste into high-value raw materials and rewrite the rules of circular fashion.

Faced with the overriding imperative of mitigating the effects of climate change and growing pressure on natural resources, the textile industry needs to reinvent itself. This is of the utmost urgency in the age of disposable fashion, in an industry responsible for around 10% of global CO₂ emissions, where only 1% of the 100 million tonnes of textile waste are recycled worldwide.

Waste avoided... and even reintroduced into production

It is against this background that SANKO, through its subsidiary RE&UP, has developed innovative processes to transform textile waste – even complex or poor-quality waste – into Next–Gen fibres that may be repurposed within the textile industry. In 2024, this project received a €70 million loan from Proparco to support green innovation and combat carbon emissions in the textile sector, thereby actively contributing to climate change mitigation.

As Andreas Dorner, General Manager of RE&UP explains, “We provide a solution that not only reduces the environmental impact by avoiding landfill and waste incineration, but also feeds textile waste back into production, contributing to a global vision of an evolving circular economy for the fashion industry.”

At last - low-end textiles recycled using a “truly unique” process

The exclusive recycling technology developed by RE&UP can process large volumes of textile waste, including the complex cottonpolyester combinations often found in today’s garments. Mahmut Bayram, industrial engineer at SANKO adds that “Our technology can recycle both cotton and polyester rich textiles, even when these are mixed together. With the technical expertise of French company Andritz Laroche, this unique industrial process comprises several different phases.

The first step involves sorting, cutting and opening the fibres. The physical separation of the different components then allows the solid and unwanted fabric to be removed; this material is then moistened to preserve the fibres’ initial qualities. Lastly, thanks to an innovative chemical-free bleaching process, cotton and polyester are separated to obtain Next-Gen cotton and Next-Gen polyester with virgin like quality and performance.

Mahmut Bayram goes on to explain that “Until now, it had been impossible for the recycling industry to process coloured or mixed clothing. The uniqueness of our innovation makes it possible to decolourise the fibres and separate cotton from polyester while preserving the quality. We produce a recycled fibre that is virtually like new and ready to be used by the textile industry without any loss of quality.”

Özde Demirturk, Director of Sustainable Finance at SANKO Group highlights the uniqueness of the process: “It’s a world first. The RE&UP process guarantees the long-term sustainability of cotton and polyester by giving value back to thousands of tonnes of waste that were previously considered non-recyclable.” Moreover, this waste ends up as piles of harmful old clothes on beaches and coastlines, for example in certain West African countries.

Greenhouse gas emissions, water, energy: a spectacular reduction

The results achieved using RE&UP technology are indisputably delivering significant reductions in water usage and CO2 emissions, when compared to conventional virgin fiber production. This is accompanied by a massive reduction in energy consumption, thanks in particular to the installation of 33.5 megawatts of photovoltaic panels at RE&UP’s industrial sites.

Proparco helped finance the new (mostly cotton) textile recycling plant in Gaziantep, an essential step that will help to achieve the Group’s 200,000-tonne mechanical recycling capacity target by the end of 2026. The aim is then to reach 1 million tonnes a year by 2030, thanks to international expansions (see the interview with the General manager of RE&UP). This development is based on an integrated business model, covering not just textile recycling, but the recovery of plastic waste (PET), the construction of innovative ultrafiltration plants to reduce the water footprint, and a proactive raw material traceability strategy.

The key role played by Proparco and French industrial expertise

Proparco played a key role in helping RE&UP to scale up its operations by structuring a €70 million financing facility, backed by €45 million worth of sub-participation from Agence française de développement. Designed with favourable terms, including maturities tailored to the scale of the investments, the facility supports RE&UP in rolling out its technology and expanding its industrial footprint. This ambitious and technically advanced partnership between Proparco and SANKO stands out for its strong alignment with both environmental and industrial goals. It also supports the French SME Andritz Laroche, a strategic industrial partner of RE&UP.

Beyond the benefits observed in terms of mitigation, the Proparco / RE&UP partnership also has significant social benefits as it should create more than 200 jobs every year over the next five years, paying salaries above the legal minimum. The project also enhances gender equality by increasing the proportion of women in operational jobs. Thanks to its commitments, RE&UP has obtained the 2X Challenge label, an international programme designed to channel capital towards private sector initiatives that benefit women.

Towards a circular and sustainable textile industry

Thanks to this project, the SANKO Group is shaping a new industrial vision. One that combines technological innovation with environmental responsibility. Built on strong international cooperation between France and Turkey, both industrially and financially, RE&UP serves as a full-scale testbed for a low-carbon textile economy. It offers a tangible, scalable solution to addressing the root causes of climate change.

Andritz Laroche, innovation à la française

French-based company Andritz Laroche is a major player in fibre processing, recycling technologies for textiles and non-wovens (i.e., materials obtained by assembling textile fibres without weaving or knitting). The business was founded in 1926 in Cours-la-Ville, between the French cities of Lyon and Mâcon, and is renowned for its expertise in designing machines and complete lines for mechanical recycling of textiles, particularly based around the use of shredding.

Laroche has been part of the Austrian Andritz Group since 2021 and has a technical centre in the Rhône region. This state-of-the-art facility is used to test technical solutions and validate them on production lines, a major advantage when developing innovative textile recycling projects.

It is this expertise and capacity for innovation that enabled Andritz Laroche to partner with Turkish textile giant Sanko when this group launched its new recycling technology company RE&UP in 2023. In total, Sanko has ordered five mechanical recycling lines from Laroche.

Expertise that drives innovation in the textile industry

As Andreas Dorner, General Manager of RE&UP explains, “To truly push boundaries, you need to partner with companies that also have expertise in their specialist areas. Andritz Laroche has expertise in sustainable textile recycling process engineering and it has achieved excellent results. We knew that by joining forces, we could contribute to a major change in the sector.” The challenge with this project was to ensure that the technology deployed was perfectly adapted to RE&UP’s needs and that the machine configuration process ran smoothly once it was delivered to the customer.

Ultra-adaptation to customer requirements

Francis Elias Junker, sector sales director at Andritz Laroche adds that “We sell a project, not just a machine. Once the machine has been delivered, we install it, observe how it operates on site and adapt it in detail so that it does exactly what it was sold to do. Every production line is a unique project. Indeed, we produce a lot of equipment at our home site in Coursla-Ville, the legacy of a century of industrial craftsmanship.”

By way of conclusion, Andreas Dorner explains that “We are using Andritz Laroche’s technology to meet this challenge together. As we continue to develop RE&UP around the world, we are counting on Andritz Laroche for additional support so that we can meet the needs of our customers on a global scale.”

Following successful deployment of the pilot plant in Turkey, RE&UP consumer goods recycling hubs will be created in Europe, Asia and America, thereby scaling up the comprehensive solutions available for textile recycling and circularity in this industry worldwide.

Read the interview with Andreas Dorner

“Our goal: to create a global network of circular textile recycling hubs”

RE&UP’s General Manager, Andreas Dorner, discusses the technical challenges encountered, the expansion strategy of Sanko Group’s subsidiary, and the key role of the partnership with Proparco.

Published on November 4, 2025